MY EXPERIENCE

last 18 years of my career in offshore construction and installation

- 6,5 years QA-Management for EPCI-projects (offshore windfarm foundations).

- 3 year QHSE-Management in offshore installation works.

- 8 years QHSE-Management in heavy lift (until 3300 T)

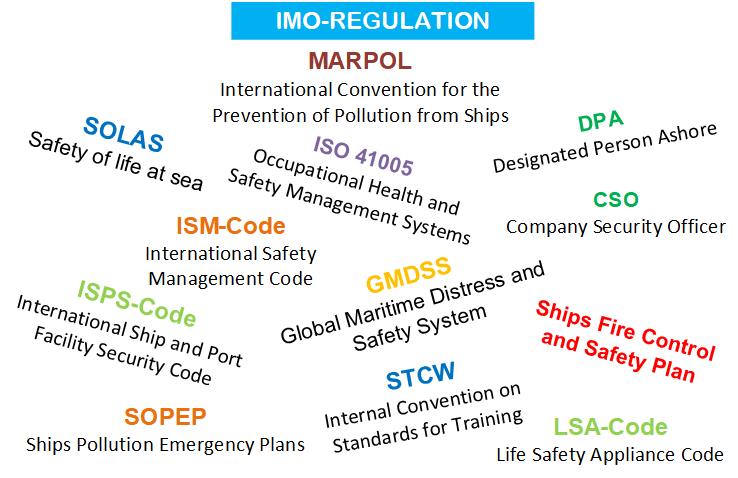

- Development and implementation of a integrated QHSE management system for offshore installation activities, including ISM (IMO-regulations) for the special purpose vessels and development of a QA management framework for EPCI projects.

Experience in qa management and QMS

- QA Management on Offshore EPCI-projects.

- Development and implementation of integrated QA management systems (ISO 9000 series and TQM) for both manufacturing and project activities.

- Experience with ISO 9000 series: ISO 9001, ISO 9004, ISO 10005, ISO10006, ISO 21500.

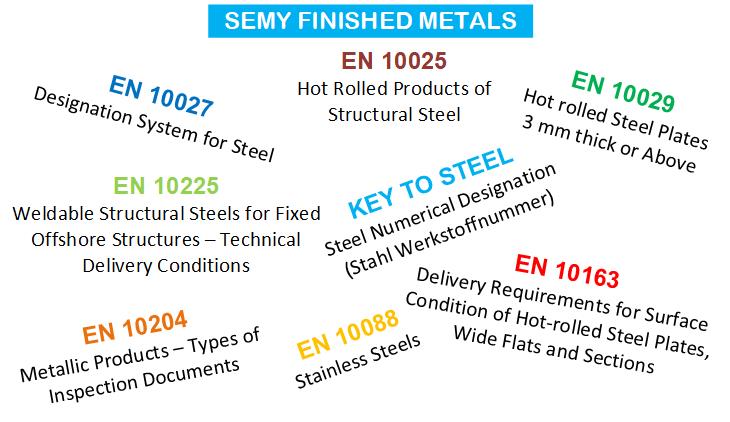

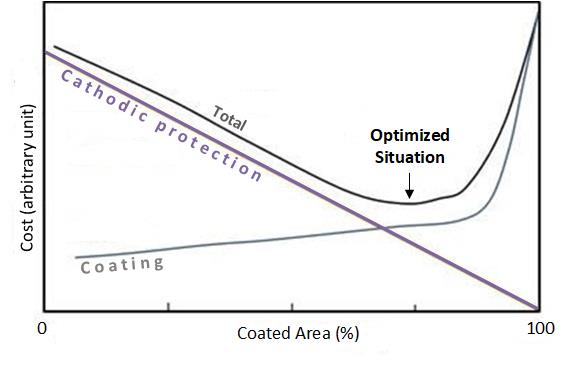

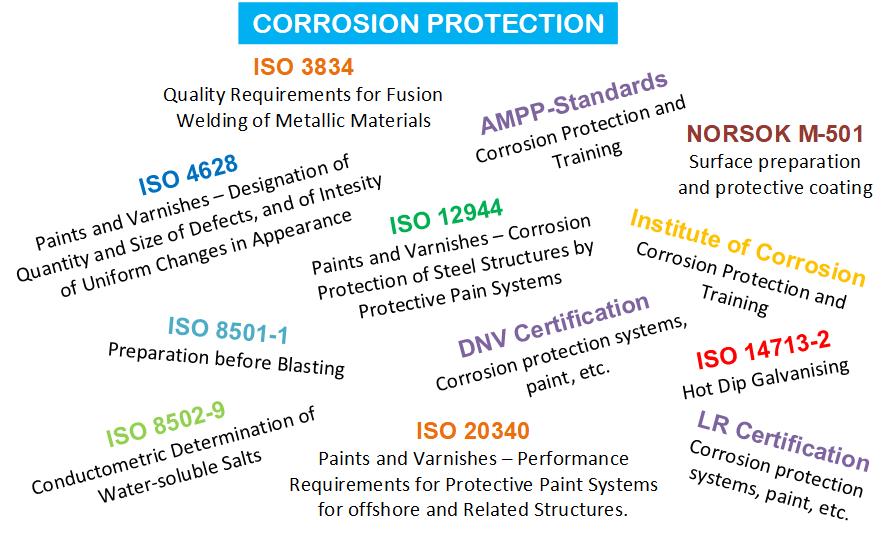

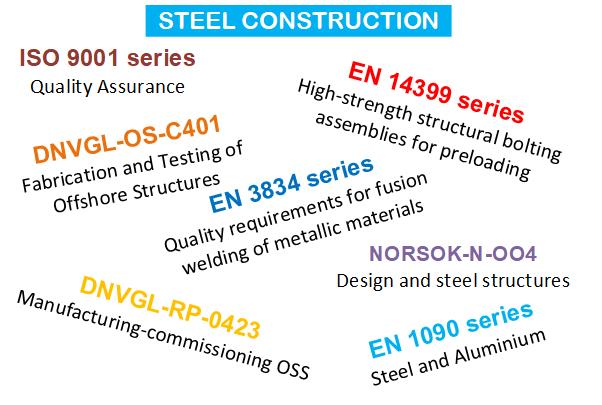

- Experience with multiple standards and regulations related to steel construction, corrosion protection, geometric product specifications, welding, semi-finisched metal products, DNV/NORSOK,etc.

- Development of a QA management framework for offshore EPCI projects

- Development/implementation of a quality costs system.

- Chairman of a quality committee with as participants: production manager, foremen and other department managers.

- Application of the basic principles for meetings to achieve the intended outcome of the meeting with a minimum of time and burden on the participants.

- Dealing with defects with suppliers and clients.

- Process mapping for both manufacturing activities and project activities.

Experience in Documented information management

- Mapping and implementation of documented information management processes.

- Application of relational databases.

- ACONEX (Project management software from Oracle that includes an Electronic Document Management System that allow Stakeholder to share documents with each other).

- Manage a huge amount (30,000 items) of documented information with the project management software “ACONEX” which is based on a relational database.

- Share point (Web-based document management system with features for collective document preparation and for sharing with authorized users through advanced searches).

Experience in HSE management and systems

- H&S for offshore construction activities. Prevention advisor according to the Belgian legislation.

- DPA and CSO according to IMO regulations.

- Coordinating and coaching QHSE-engineers working on offshore installation projects.

- Development and implementation of a HSE management system for “offshore construction works”, based on European directives, EU harmonized standards, Belgian Health & Safety Legislation, UK-legislation, German legislation, OHSAS, VCA 2004, ISM, ISPS, company activities risk assessment.

- Knowledge and experience with IMO-regulations as SOLAS, MARPOL, STCW95, ISM, ISPS etc. (IMO = International Maritime Organisation)

- Incident/accident investigation for offshore installation activities.

- Heavy lift calculations according to Noble Denton code (currently DNV-rules).

experience in Technical disciplines

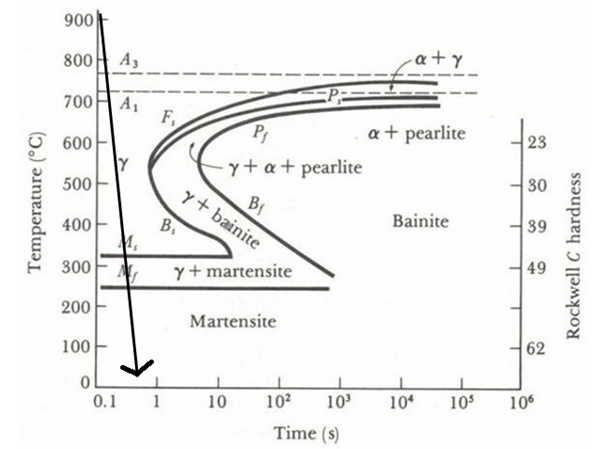

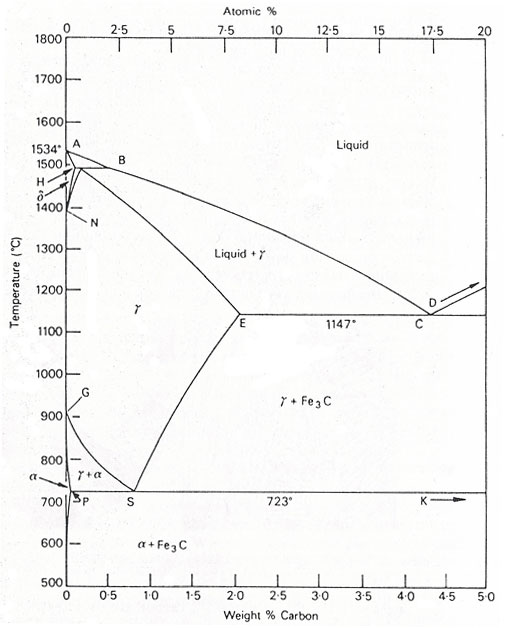

- Heat treatment, surface treatment of machinery parts, metallurgy (One year experience in industrial test lab) and related production equipment.

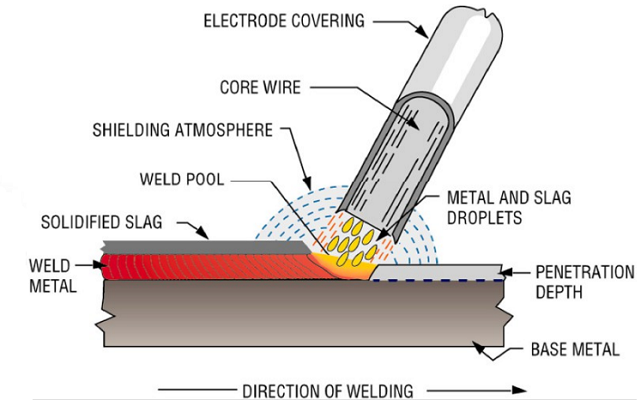

- Welding technology and related standards.

- Industrial automation: PLC, PID control, pneumatics, hydraulics, AC-motor drives, sensors etc.

- Engineering of industrial burner applications: Thermodynamic calculations, pipe train, automation of burner control, integration in production processes.

- Mechanical engineering/design.

- Start-up of comprehensive industrial equipment and follow-up at the client‘s premises.

Particular experience

- Managing 10 employees in a quality departement for mechanical assurance and quality control. (5 years)

Included reforming the department from quality control to quality assurance and restructuring from 10 quality inspectors to 5 quality assurance specialists in the first 2 years of the assignment as QA-Manager.

- Project Manager on an offshore heavy lift project to remove parts of a concrete jetty and dolphins (5 months). Included rigging calculations for lifting 300 until 500 T according to the former standard Nobel Denton 0027/ND.

- Mapping of various processes in production and project environments to increase quality management.

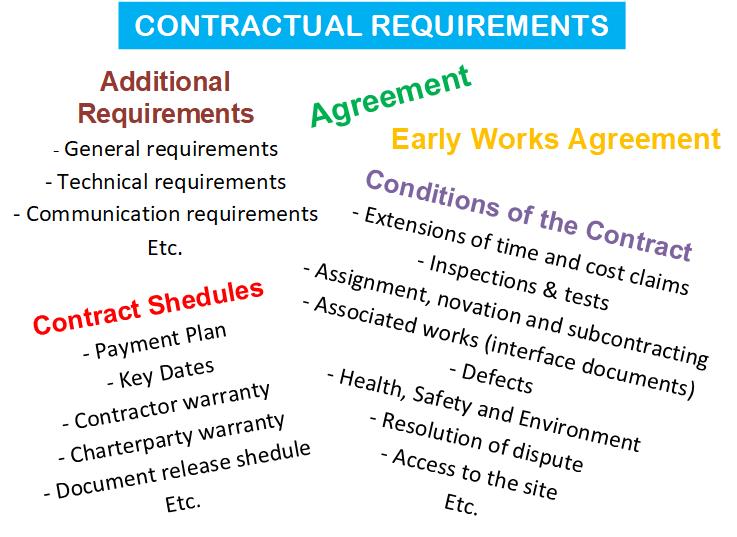

- Contractual requirement for EPCI-project based on FIDIC. Contracts Employer/Contractor as well as Contractor/Supplier.

- Engineering of industrial burners: Thermodynamics, automation of burner control, integration in production processes.

- Chairman of a quality committee with as participants: production manager, foremen and other department managers.

- Coaching QHSE-Engineers working on offshore sites.

- Troubleshooting in industrial installation and equipment.

- Application of Machinery Directive and CE marking for industrial equipment.

- Project realisation in industrial automation. (Small and medium sized projects)

- Mapping calculation of cost price, yield, capacity for manufacturing and automation with software applications. (Analytic accounting)

EXPERIENCE IN GRAPHICAL IMAGES

Document Management Platform

"Aconex"